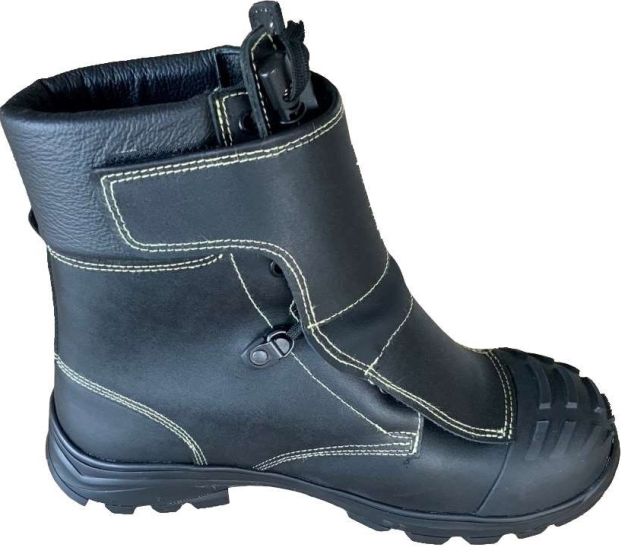

Charnaud® METAL-SAFE® Hot Metal Boot

SKU

ALU-BOOTS

£245.00 (exc. VAT)

Leather smelter and furnace boot with 1,000 degrees heat resistant sole, external metatarsal guard and lace up system incorporating a quick release zipper system.

Test performance exceeds EN ISO 20349 Personal protective equipment — Footwear protecting against risks in foundries and welding

Also meets BS EN 15090:2012 Footwear for firefighters

Footwear for the molten metal and foundry industry. Protective equipment against Molten metal splash, flames, heat, heavy industrial environment.

- Upper: Full grain leather.

- Lining: Leather.

- Outsole: High heat resistant compound. Oil and acid resistant, non-slip and nonmarking.

- Midsole: Flexible and puncture resistant.

- Toe cap: Light, Impact resistant to 200J

- External Metatarsal Guard: Non-magnetic, permanently attached, impact resistant

- Stitching thread: Ultra-high heat and molten metal resistant.

- Molten metal splash, heat and flame resistant. Molten metal single dip exposure up to 1000°C.

- Construction: Light weight design (including toe cap) ensures maximum comfort and minimum foot fatigue.

- Puncture resistance: Light, flexible puncture resistant midsole.

- Electrical shock resistant (EH): Outsole electrical shock resistant to 18kV (dry conditions).

- External metatarsal guard protection.

- Quick release system to take the boot off in case of an emergency.

- Sizes: UK: 6 – 13.

Standards

- EN ISO 20349:2010.

Al = Resistance to effect of molten Aluminium,

Fe = Resistance to effect of molten Steel,

E = Heel energy absorption,

P = Penetration resistance,

M = Metatarsal protection,

CI = Cold insulation of sole complex,

HI1 = Heat insulation of sole complex,

FO = Out sole resistance to fuel oil,

WRU = Upper water penetration and absorption resistance,

HRO = Outsole resistance to hot contact,

SRC = (SRA + SRB) Slip resistance - ASTM F2412-11:2011 EH sole system (18kV dry conditions).

- CE Certified.

| Branding | Reece |

|---|

Write Your Own Review

UK

UK US

US