Arc rated Insulating Gloves 360mmL x 1.6mm Class 0 (1000V)

2-in-1 Arc rated Insulating glvoes

These innovative 2-in-1 gloves give class 0 insulation and 14cal/cm2 arc flash protection.

The thickness of <1.6mm gives the wearer good dexterity and an improved sense of "feel" over composite arc rated insulating gloves.

Arc rating:

ASTM F2675 ARLim 14cal/cm2

IEC 61482-1-2 Box test APC - 2 (0.5s/7kA)

Electrical insulating gloves offering personal protection against electrical shocks and arc flash when working on or near live equipment and manufactured in full compliance of IEC 60903:2014 and EN 60903:2003 standards.

To avoid cuts and nicks in heavier use the user should wear leather overgloves for mechanical protection

14cal/cm2 arc rated Electrical Safety Gloves 360mmL x 1.6mm thick Class 0

SHOULD BE USED WITH A LEATHER OVERGLOVE FOR MECHANICAL PROTECTION

Due to the gloves natural latex base our insulating gloves offer you high dielectric characteristics. The Insulation of hands is determined by the class number and nominal supply voltage.

- Fully insulating gloves each test stamped

- Manufactured to EN60903

- Pneumatic glove tester available to carry out your own air inflation test as recommended by the EN60903 and IEC903 standards (for class 00 & class 0)

- Mechanical resistance obtained with a leather over glove

- High dielectric characteristics

- Ergonomic shape

- Lightly powdered

- Easy to slip on and off

- Natural latex base

- Length 360 mm

- Category AZC

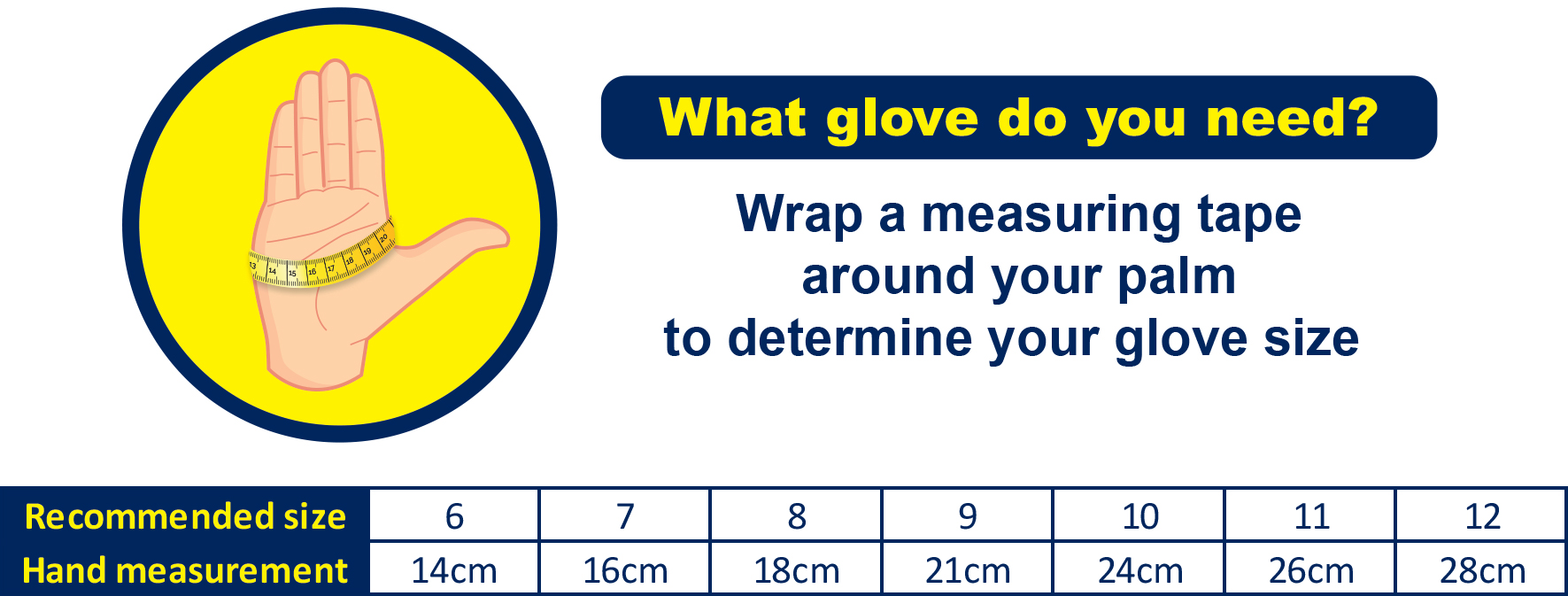

- Various sizes available

- Cut Edges

| Type | Gloves |

|---|

How long do the Latex insulating gloves Last?

As the purpose of these gloves is to provide a high level of protection against potentially high voltages, it is important to check the integrity of the gloves as much as possible. The following is recommended:

- Class 00 and Class 0: These gloves are suitable for use as long as they have not been physically damaged. If they have been damaged (for example cuts and nicks) we would recommend immediate replacement. A simple air test (using a pneumatic glove tester or simply blowing in air and twisting the sleeve to check for leaks)

- Class 1 and Higher: These gloves must be visually inspected and tested, with a dielectric test, for suitability every 6 months from the date of manufacture onwards. The manufacturing date can be found on the product packaging.

UK

UK US

US