Lock Out Tag Out Locks vs Standard Security Padlocks: The Differences Explained

When we talk about padlocks, most people think about the role these devices play in securing valuables and acting as a deterrent for would-be thieves.

However, in the field of electrical safety and safety at work where Lock Out, Tag Out and LOTOTO specialists Reece Safety operate, safety padlocks have a separate purpose. They differ significantly in terms of design, purpose and application, and play a vital role in ensuring the safety of operatives working on machinery and equipment.

This post will examine the unique differences between the two types of padlocks, and explain why LOTO locks and padlocks are so important.

Find out more about Lock Out, Tag Out in this post from Reece Safety on LinkedIn.

Security Padlocks

So what is a security padlock? Essentially, these devices are used to secure a wide range of different locations and individual items, from gates, sheds and containers to bikes and even lockers.

There are many different types and designs of padlocks, including anti-tamper designs, long shackle styles, keyless combination padlocks, anti-tamper options and closed shackle padlocks, all designed and manufactured for specific applications.

For ordinary security padlocks often used and left outdoors for lengthy periods, weatherproofing may also be an important design point, but this is far less relevant for LOTO locks

LOTO Locks

A LOTO lock or safety lock has a different purpose. These padlocks are designed for use in Lock Out, Tag Out procedures, to prevent the accidental energisation and start-up of machinery which has been deactivated, usually for maintenance purposes. They play an essential role in keeping people safe while they carry out this type of work.

So what makes a safety lock special? They are designed for this purpose, often using internationally recognised colour coding to denote different types of activities. There is a wide range of different designs available, they are precision-built to prevent accidental crossovers and many feature specialist options such as anti-spark shackles for added safety in use.

Choosing the right supplier is essential. Many safety padlocks are designed and manufactured by security padlock manufacturers, who are designing for a more general security market and are not as close to the requirements of safety lock users for LOTO requirements. Reece Safety deals only in safety locks for LOTO and LOTOTO procedures, supplying high-quality products and accessories produced for this very specific market.

When to use LOTO Locks & Security Padlocks

It is important to recognise that standard security padlocks are designed for security applications and not for safety-specific uses in situations where energy could be released and pose a danger to life.

With standard security padlocks, the focus is on securing an item or valuable, and the number of ‘differs’ (possible keys which may operate a given lock) is not a key criterion. As an example, if you examined 20 high-security locks off the shelf from any DIY outlet, it is even possible that you might find a duplicate.

When locks are being used to preserve life in high-risk industrial and commercial applications, this is not acceptable. LOTO locks manufactured by Reece Safety and other LOTO lock manufacturers are designed expressly to assist with lockout tagout procedures and safety compliance regulations.

Although they are sturdy and durable, LOTO locks are not intended for more general security applications. For example, they do not feature hardened shackles, which means they can be cut off more easily if they are accidentally left on, following a robust process to investigate why.

LOTO Locks in Detail

Usage

LOTO padlocks are put in place on equipment once the equipment has been fully isolated from its energy source, complete with a visible tag to make it clear that this equipment is not to be used or re-energised. This means necessary inspection and/or maintenance work can be carried out in complete safety without incurring risk or hazard.

Key features

LOTO padlocks are durable and designed to ensure that the equipment they secure remains inoperable. They are difficult to pick, highly secure and identifiable through bright colours and associated labelling systems denoting who is responsible for the machinery lockout in progress. These colours are standardised to identify the type of lockout.

LOTO padlocks are designed and manufactured specifically for LOTO safety applications. More than one padlock may be used on any specific piece of equipment.

What are they made of?

For LOTO applications in the UK, brass locks with brass shackles are often the safety padlock of choice, as they offer non-conductive properties for use in electrical situations and are also resistant to extremely high temperatures.

Nylon body colour-coded safety padlocks offer an efficient and cost-effective alternative, also corrosion-resistant and non-conductive. Aluminium-bodied safety padlocks are also available, again colour-coded and resistant to corrosion for use in applications where exposure to chemicals may be an issue.

Optional extras include clear protective covers and extreme conditions protective covers for use in exceptionally aggressive environments

Main benefits

LOTO safety padlocks play a vital role in identifying and ensuring that power sources are completely isolated. In the UK, compliance with Electricity at Work regulations requires that defined steps are taken to ensure that equipment cannot be accidentally or deliberately recharged when work is carried out on or even near each piece of equipment.

Employers are required to provide appropriate Lock Out, Tag Out devices that are durable and identifiable. The procedures are critical for worker safety, with standardised and reliable LOTO procedures providing a standardised framework for saving lives.

Standard Padlocks in Detail

Usage

By contrast, standard security padlocks are designed and manufactured for use in both commercial and residential settings, for non-safety applications. They act as a deterrent to thieves and provide differing levels of performance and security, dependent upon design, material and configuration.

Key features

There is an extensive range of choices in terms of the different types of security padlocks and locking mechanisms available on the market, from keyed and combination locks to smart and even high-security padlocks.

Security padlocks are usually specified and selected based on the level of security required, with high-risk applications demanding high-security solutions, whilst less valuable items requiring lower levels of protection may only need a basic security option. Matching the level of security required with the available choices will ensure an appropriate and cost-effective solution.

What are they made of?

How durable a padlock will be in the long term will depend upon the material of the padlock body and the design of the casing and internals. Padlocks made from hardened steel are better equipped to withstand external attacks such as sawing or cutting.

The majority of security padlocks are manufactured from brass, hardened steel or aluminium; each material has its strengths and limitations in terms of weight versus performance.

All padlock internals are brass, but there are different combinations for body and shackle materials, dependent upon applications. Weather-resistant materials and weather-sealed designs are available to guarantee longevity for outdoor use

Main benefits

Security padlocks offer numerous benefits, from the protection of privacy, and temporary secure storage such as bicycles and other mobile assets to deter thieves, in the long term. They provide a convenient, affordable and easy-to-use solution for many different environments, valuables and applications.

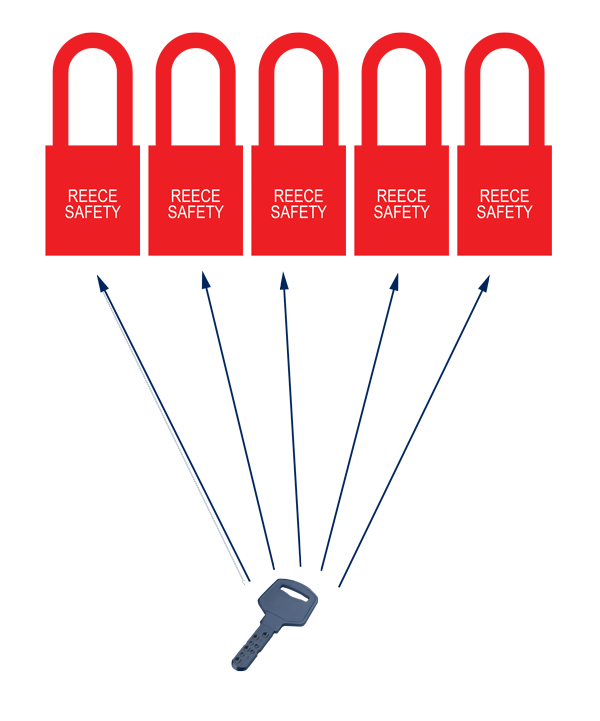

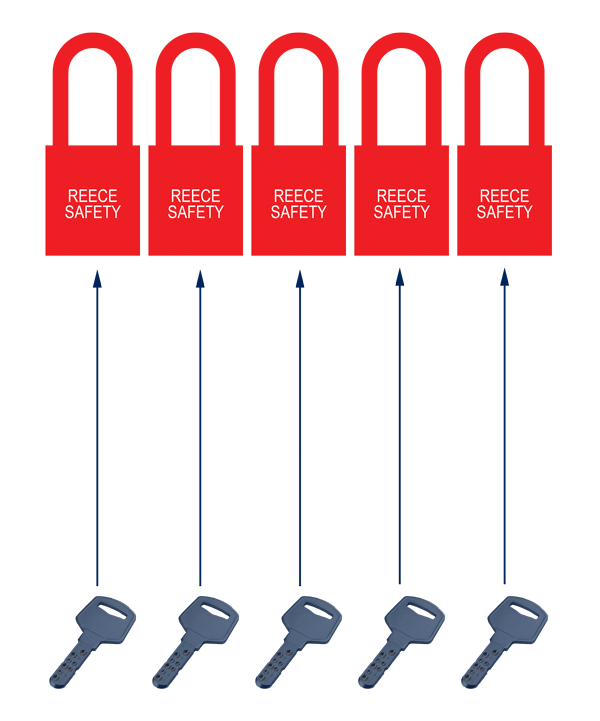

A major benefit of LOTO Locks is the high number of ‘Differs’

What does this mean? Every padlock has many ‘differs’, which is a term used by locksmiths to describe the number of keys which may open a lock. This is dependent upon the individual design of the key, the number of locking components in each lock, the many different positions each of these components may be placed in and then compounded by the tolerances of the lock itself.

LOTO locks are characterised by a particularly high number of differs, which makes them particularly secure for as required by potentially life-preserving applications.

Most applications require few security padlocks and are therefore available with a limited range of differs. As a result, it is a fact that the same key may well operate and open several different basic security padlocks.

By contrast, safety padlocks offer a vast number of guaranteed differs. This means that no crossover (where one key will operate many different padlocks) is possible. It is extremely unlikely that a LOTO padlock can be unlocked by any key other than the one specific to that padlock.

For LOTO applications, the strength of the padlock is less important than the potential for it to be opened by anything other than a deliberate act.

So why should you choose safety padlocks from Reece Safety?

- Reece Safety boxes are colour-coded to match the lock colour

- The unique lock number is etched onto the box making identification easy and unequivocal

- Reece Safety LOTO padlocks are packed in sequential numbers, with a box of 10 containing locks numbered 1-10

- Each case contains 10 boxes of 10 numbered 1-100, making number control and management so much easier for LOTO procedures

- The lock number features on both lock and key as standard

- The dimple key cannot be duplicated by other locksmiths

- Keys can be inserted in either orientation for ease of use

- The lock is key retaining as standard, and the key cannot be removed when the shackle is open

- Reece Safety provides up to 120,000 differs

- The Reece Safety Sentinel system is used to record the lock numbers provided to end users when requested, ensuring no duplicates are supplied on subsequent orders

Manufacturing Standards

OSHA standards (Occupational Safety and Health Administration) standards state that “… lockout tagout devices should be durable, standardised, substantial and identifiable …” and safety padlocks must meet these standards.

There are several standards governing security padlocks, including:-

- BSEN 12320: locks are classified according to use, corrosion resistance and strength

- Standard Performance Specification for Padlocks: environmental, functional, operational, and security requirements for padlocks.

- Sold Secure: a guide to the security level of a padlock.

- CEN: European standard covering the security level of a padlock.

In summary

LOTO safety padlocks may work similarly to security padlocks, but they are designed and manufactured with a very specific intended use in safety compliance and should not be confused with their security counterpart. View the comprehensive range of Reece Safety padlocks for LOTO applications.

UK

UK US

US