What are the Arc Flash Labelling Requirements?

Arc flash labels play a vital role in maintaining electrical safety, and communicating important information to people working in the vicinity of equipment which may be energised. They are used to communicate data with the necessary information on the potential hazards present and also the appropriate safety precautions to take.

To ensure optimum safety for personnel, arc flash labels carry comprehensive information on the potential arc flash and shock hazards present, indicating the category level and description of appropriate Personal Protective Equipment (PPE) for the application. They are also referred to as arc flash warning labels, arc flash stickers or electrical equipment hazard labels.

At Reece Safety, we specialise in the supply of a comprehensive range of differently rated arc flash clothing and electrical safety gloves, in support of the arc flash labelling safety initiative. All of our products match the specifications and performance ratings carried on arc flash labels.

Where is arc flash labelling required?

Every piece of electrical equipment which has the potential to present an arc flash hazard should carry an arc flash label. In many cases, electrical equipment may need to be energised during procedures including examination, maintenance, servicing and repairs. The list is extensive and includes equipment such as switchboards, panel boards and transformers, industrial control panels, distribution boards, enclosed circuit breakers, motor control centres, disconnects and external variable frequency drives, to name but a few.

Certain pieces of electrical equipment do not require arc flash labelling, including unfused safety switches, unfused disconnects, standard motors, lighting control panels and internal meters.

The National Fire Protection Association (NFPA), a global not-for-profit organisation ‘devoted to eliminating death, injury, property, and economic loss due to fire, electrical, and related hazards’ has produced NFPA 70E, also referred to as the Standard for Electrical Safety in the Workplace.

Arc flash labelling is covered in NFPA 70E Article 130.5, produced by the National Fire Protection Association. This standard was developed to provide clear guidance on electrical safety practices to protect people who work in electrical environments and could be exposed to significant risk from electrical hazards whilst conducting their professional roles.

What should be included on an arc flash warning label?

Arc flash labels are required to carry information on the existing hazards such as shock and arc flash. Current arc flash label requirements also demand they carry information on other relevant areas such as the categories of personal protective equipment and arc flash protective clothing demanded by the environment to keep people safe. Correct arc flash labelling means people working in the area have all the information they need to make safe decisions around arc flash hazards.

Information on arc flash labelling should be provided on the following to comply with safety regulations.

- Available incident energy level (expressed in cal/cm²), which illustrates the potential for thermal energy and the potential severity of an arc flash. The available incident energy level guides decision making on the correct level of PPE for the job at hand.

- Guidance on the minimum category level of PPE required in line with the available incident energy level, covering items such as protective clothing, eye protection, gloves and other appropriate equipment to protect against the dangers of an arc flash incident. In the UK, these items are governed by European standard BS EN IEC 61482-1-1.

- Arc flash boundary information, detailing the area around an arc source where people could be exposed to a thermal incident of more than 1.2 cal/cm² (the threshold value of incident energy for second-degree burns). This information enables workers to assess safe working distances and boundaries to avoid the danger of arc flash.

- Arc flash labels should also include nominal system voltage for the equipment and clear equipment identification information.

- The arc flash label should also show the date it was last updated so that workers can be sure the information is up to date and accurate.

These are minimum arc flash label requirements in compliance with safety regulations; arc flash warning labels can also carry additional information to provide an improved understanding of the potential hazards.

Who is responsible for equipment labelling?

The NFPA standards clearly state that it is the owner of the electrical equipment who must assume responsibility for arc flash risk assessment and installing and maintaining these labels. It is not enough to just put arc flash labels in place, equipment owners need to ensure they remain in legible condition over time.

It is good practice for companies to schedule regular audits to check the condition of arc flash labelling to ensure it continues to be legible, particularly as much of the equipment will be operating in demanding environments. Employees should also be trained to understand the importance of arc flash labelling and what the labels mean in use in terms of electrical hazards.

Where should arc flash labelling be located?

Obviously, arc flash labelling needs to be visible, and should be placed in an appropriate and accessible position on each piece of electrical equipment where it can be seen and noted. Typical positioning would be on the outside of equipment enclosures on the approach, on the front cover of the equipment, on breaker doors and on the outside of cabinets and industrial control panels. As a guideline, any access cover or door that opens and exposes energised parts should carry a warning label.

What boundaries are shown on arc flash labelling

Boundaries are an important consideration and an essential part of every arc flash warning label.

Arc Flash Boundary

This is the total area around a potential arc source where the available incident energy level is above 1.2 cal/cm², which means that anyone located within this boundary could experience second-degree burns in the event of an arc flash event. Anyone within this boundary should wear the appropriate level of PPE.

Limited approach boundary

This refers to the distance around an exposed energised electrical conductor subject to a shock hazard. Untrained workers should remain outside this arc flash boundary unless the equipment has been safely deactivated.

Restricted approach boundary

This defines the area where accidental movement could mean tools or people coming into contact with live elements. Only trained workers should cross this boundary and must be wearing appropriate PPE including insulated gloves as well as using correctly insulated tools.

Do arc flash labels need to be updated?

Responsible companies carry out regular audits and arc flash risk assessments, and the NFPA 70E regulations state that updates should be carried out whenever equipment is installed, replaced, modified and/or renovated. Arc flash labels should be amended accordingly. Assessments should be reviewed at least every five years, as changes to an electrical distribution system can alter arc flash risk hazards.

Key elements of an arc flash label

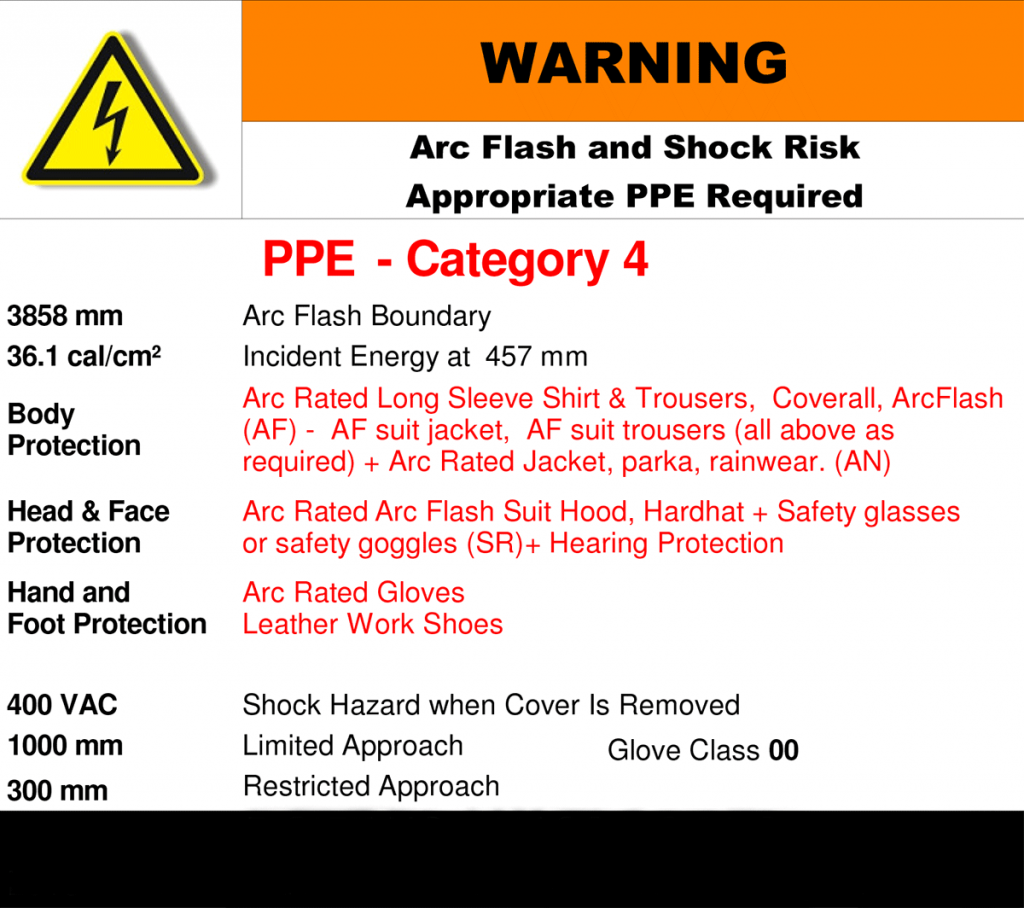

Arc flash labels like the example above demonstrate a clear warning of the arc flash and shock risks.

Included is an indication of the personal protective equipment category required, together with the specification of the arc flash boundary.

More detailed information is also provided on the arc-rated PPE required for this environment and application, covering body protection, head and face protection and hand and foot protection.

Restricted approach information is also specified.

In this example, the location and name of the company who have performed the assessment has been removed for privacy.

Is Arc flash labelling required by the Health & Safety Executive?

In the UK, legislation is risk-based, which means that duty holders are responsible for managing the risks they create. There is no specific guidance document on arc flash, although current HSE guidance does emphasize the seriousness of arc flash hazard.

In the US, the Occupational Safety and Health Administration (OSHA) electrical safety regulations require companies to comply in full with NFPA 70E. In addition, OSHA has its specific requirements which means electrical equipment has to carry information on voltage, current, wattage and other aspects of operation. The objective is to provide workers with as much information as possible to ensure they can work safely without the danger of injury through arc flash.

OHSA also has other requirements in terms of signage, barricades, tags and attendant personnel to ensure people are adequately protected from the risk of arc flash, electric shock and burns.

Summary

Arc flash labels play a vital role in helping to ensure safety at work by providing immediate, clear and accurate information on boundaries and levels of PPE required. For access to a comprehensive range of high-quality arc flash-rated clothing and accessories, visit the Reece Safety catalogue.

UK

UK US

US